This project was part of a school project at IMT Atlantique in the context of socio-ecological problems. We worked with a permaculture garden, le Jardin Vivrier de Boisbonnes, near the school. The goal was to build a green-greenhouse, that is a greenhouse with as little impact on the environment as possible. Moreover, we decided to make the greenhouse look great. That is why we designed a geodesic greenhouse. This shape approximates a half-sphere with triangular faces. It is much more complicated than the typical rectangular greenhouse.

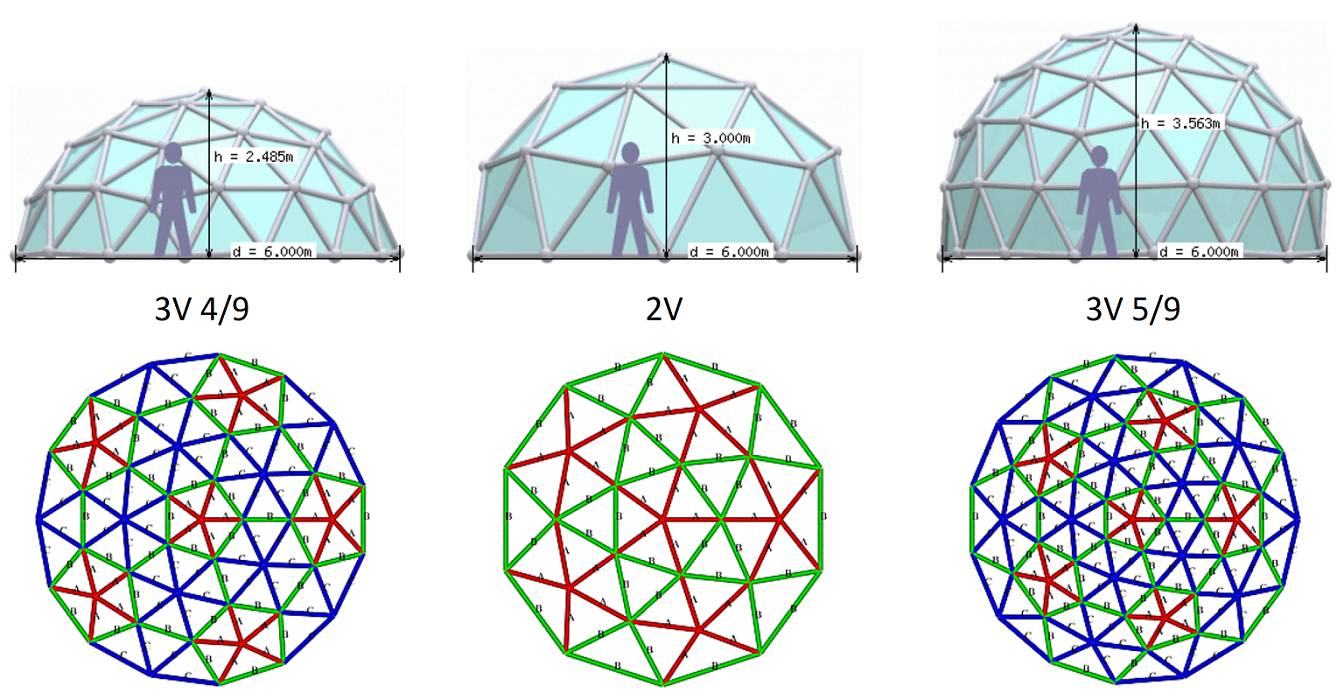

We were the first to work on the project. I was with another student. She was tasked with managing the project and contacting suppliers and I worked on the technical aspect. Geodesic greenhouses come if different configuration, primarily the resolution of the sphere, that is the number of triangle. We chose a 3V 5/9 shape. It contains more triangles and is taller than the 2V geodesic dome and requires more smaller triangles. To have enough volume inside for plantations and for people to stand and talk, we chose a diameter of 6m and a height of 3.5m, which is big for such a construction.

The different shapes we considered

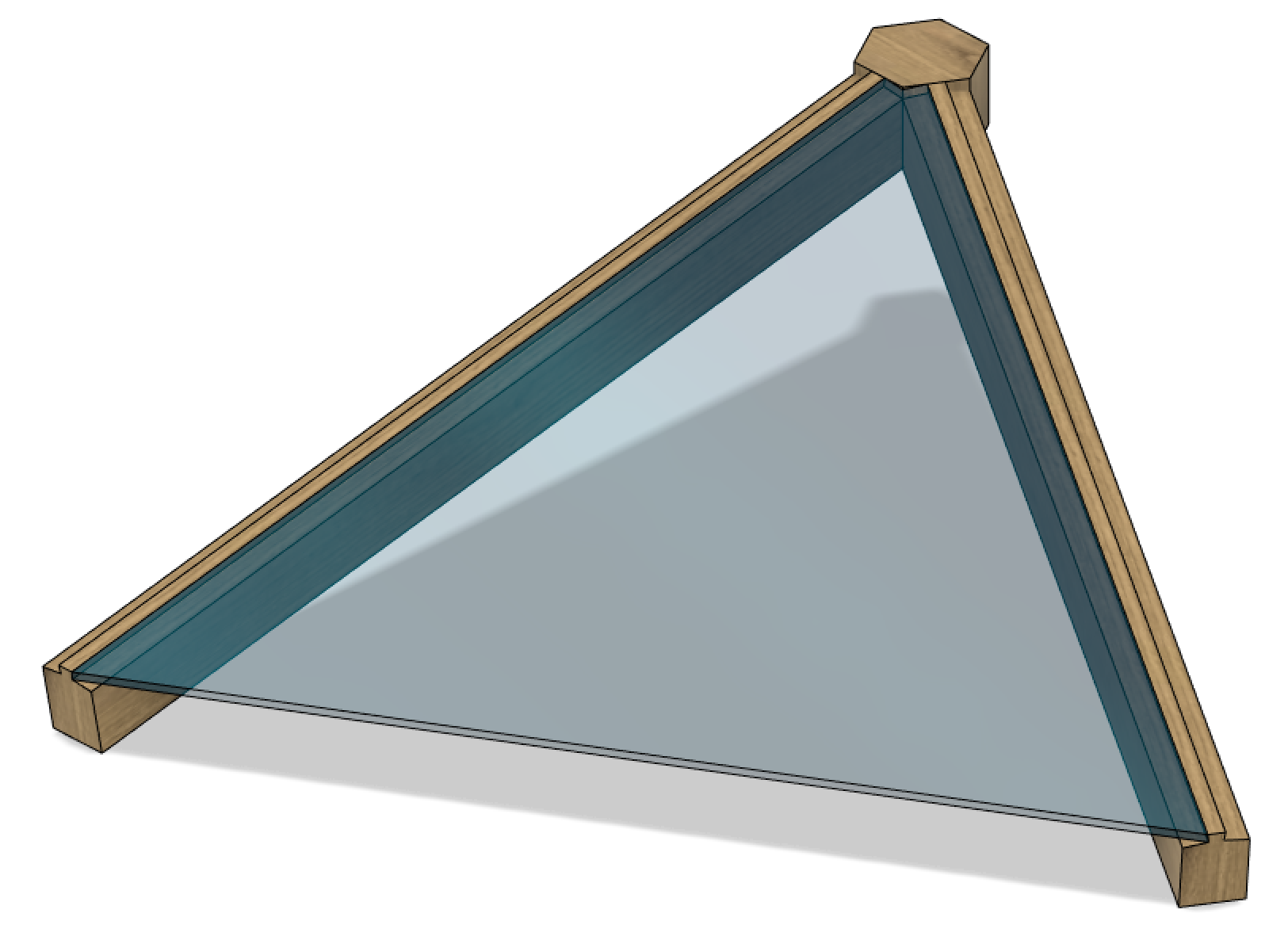

In total, we would need 165 wooden beams with a size ranging from 104cm to 124cm ; plus 105 plastic sheets of around 0.6m² ; and 62 hubs to fix the beams together. I proposed a bunch of options for how to cut, mount and fix the beams, hubs and sheets. Eventually, the option chosen was to use half-thickness beams to build each triangle separately then mount them by screwing them together along their sides.

For the plastic sheets, as this was supposed to be a environment-friendly construction, we entered negotiations with a nearby manufacturer of plastic products, Vink. They showed us a new product they had been working on : a recycled and recyclable plastic. They wanted to show off this product to improve the view people have of plastic : it doesn't have to be detrimental to the environment.

For the wood, as our semester came to an end, we passed the project to our new first-years students as well as a team of students from the nearby Ecole Supérieure du Bois (engineering school specialized in the wood industry). They were able to source and transform the wood into the required pieces. Plus their expertise confirmed the design.

One of the models I made

I made 3D models of the construction using Fusion360 as well as Photoshop images to show off what the finished structure would look like. We used them in negotiations with Vink and the next students used them to gather founds from organizations and contests.

The greenhouse was assembled over a year after, in June 2019. Here is the video the students who worked on the project at the time created (in French) :